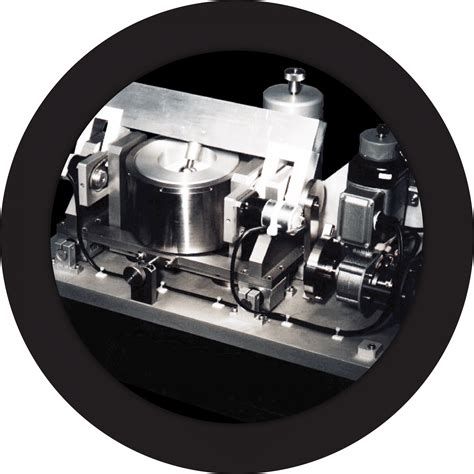

Reciprocating Friction Tester distribute|high frequency friction tester : sourcing Experimental Test-Rig. UMT- type friction tester and a high-speed-reciprocating compressor (CETR, USA) were used to study the reciprocating friction between rape stalk and bionic nonsmooth metal surface (Figure ). e range of reciprocating frequency of the compressor was Hz, and the unidirectional maximum stroke was mm. e webICQ New: Se vale tudo

{plog:ftitle_list}

web5 de jan. de 2023 · Jon was granted immunity and had a choice of Asian dishes for the other home cooks to put their own spin on, and he chose the stir fry.Subscribe to MasterChe.

Using various sensors it measures friction, wear, and adhesion of any reciprocating test setup with ease. The patented in-line 3D profilometer automatically measures topography change during the test. The module accommodates several application specific chambers, fixtures and test .

scratch test on rocks

Evaluate fuel lubricity, predict the performance of additives, and study .Evaluate fuel lubricity, predict the performance of additives, and study friction wear with our HFRR high frequency reciprocating rig. This next generation Rtec Instruments HFRR testing machine contains programmable force control (no .The standard for measurement of friction, wear, and lubrication; Wide range of testing parameters, contact geometries, and add-on options; Delivered with the reference sample kit for instrument performance verification; Integrated .

Experimental Test-Rig. UMT- type friction tester and a high-speed-reciprocating compressor (CETR, USA) were used to study the reciprocating friction between rape stalk and bionic nonsmooth metal surface (Figure ). e range of reciprocating frequency of the compressor was Hz, and the unidirectional maximum stroke was mm. e (a) Horizontal beam chassis with a slot in the center for the specimen to pass through, mounted on 2 vertical beam-columns placed on either side between the actuator and the load frame column. (b) Free body diagram of the specimen and pad in the following cases: (i) fretting test; (ii) reciprocating sliding friction test.The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels and for boundary friction measurements of .

The rig used is a slightly modified version of the one developed for unidirectional sliding by the present authors in Bin Jaber et al. [36].The approach is somewhat similar to the sled-type friction test in ASTM D1894 [37].A schematic representation of the rig is shown in Fig. 2 (with numbers indicating the key components). The contact adopted for the study was a flat .

For friction coefficient and wear rate measurement, the High Temperature Tribometer provides an ideal test setup for simulating contact between two materials at their operating temperature. . “Modelization” software for simulating Hertzian elastic contact stress and strain distribution; User-defined friction threshold auto-protection .

PCS Instruments Distribution Partnership. TriboTonic have partnered with PCS Instruments Ltd from the UK to sell, support and service both existing and new PCS Tribology equipment in Mainland Europe (except for Germany) and in addition for their fuels products in Scandinavia.. Established in 1987, by a group of research engineers from the Tribology Laboratory at .

At the initial stages of friction, the presence of interfaces notably hindered the transfer of temperature, defects, and atomic displacements in the workpiece, and this inhibitory effect weakened with an increasing number of friction cycles. The TCP phases experienced stratification due to the overall deformation they underwent. Piston ring sealing is of great importance in oil-free reciprocating compressors for high pressure application. Pressure distribution and frictional heat on piston rings have been investigated . A reciprocating friction and wear tester based on Lab VIEW was designed and built to preliminarily test the friction and wear characteristics of different materials under different test conditions .

Download scientific diagram | Linear reciprocating sliding friction and wear tester. from publication: The Relationship between the Model of the Laser Biomimetic Strengthening of Gray Cast Iron .Fig. 7 shows the comparison of the friction force variation, friction coefficient, and wear depth for UT, ST, and IT CLPRs at 150 °C. ST CLPR exhibits the lowest friction force (Fig. 7 a). As the load was increased to the high load during the test, the friction force first increased to a high value and then gradually decreased to a steady level.

Measurement and control system design and texture anti-friction test of reciprocating friction tester based on compliant mechanism November 2021 DOI: 10.1117/12.2612004Comparative study on sliding friction and wear properties of low alloy wear-resistant steel Hardox400 and NM400 at room temperature using Retc multi-function friction and wear tester. Friction tests were carried out, without lubrication and under ambient conditions, on a reciprocating friction tester in which a ball-on-flat con-tact configuration was adopted. A simulation of a reciprocating sliding test was carried out on the ABAQUS/Explicit software. The numerical model consists of a rough parallelepiped aluminum sample of 2 × 2 × 1 mm 3 in dimension and a rigid ball with a radius R = 5 mm (Fig. 1).The simulation starts with the application of a normal load F n = 1 N on the rigid ball. . Then, the .

The vertical load, friction ball diameter and reciprocating movement frequency (friction speed) are selected as the experiment factors. The cutting tools was installed in the special designed fixture on a reciprocating movement wear test machine. The wear depth increases with the increase in the Z-load, ball diameter and frequency.

Results of the 5000 cycles linear reciprocating test. a) Plots of the coefficient of friction (CoF) vs. cycles for the AlCrN and AlCrVN coatings. b), c) Optical images of the Al 2 O 3 ball against AlCrN and AlCrVN. d), e) Optical profile of the wear track, including the depth profiles taken in different zones. Blue color corresponds to the .

reciprocating tribometer

The initial decrease in friction in the reciprocating tests on 316L stainless steel, reducing ploughing friction through smoothing of surface asperities, was also observed in 10-cycle nano-scratch tests at 30 mN with a 3.7 μm radius diamond [9] (data converted to friction coefficient in Fig. 9) and in 1 N tests on copper with a 100 μm radius .The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels and for boundary friction measurements of engine oils, greases and other .Keywords: compressor, friction, valve design, minimum oil film thickness, pressure distribution, parametric study 1. INTRODUCTION Reciprocating compressors technology is mature but still has high friction losses. Measuring friction loss and friction forces is extremely complicated yet highly important for design of compressor.

2.1 Pin-on-Disk Tribometer. The most commonly used configuration for testing materials is the pin-on-disk method in either rotating or linear-reciprocating modes. The corresponding ASTM standards, G99 [] and G133 [], include the measurement of friction coefficient as well as wear rate of the sample and the static partner.The pin-on-disk setup has . The aim of the present work was to investigate the reciprocating friction and wear behavior of MCMBs-derived reaction-formed SiC submitted to dry sliding tests against bearing steel ball under different loads, in order to determine the effects that the microstructural features and properties can have on friction and wear behavior, as well as to .Friction force range: up to 20 N (5 N option) Friction force resolution: 0.06 mN (0.015 mN option) Rotating movement: Speed: 0.2 rpm to 2000 rpm (600 rpm option) Radius: up to 40 mm: Maximum torque: 450 mN.m: Linear reciprocating movement 1) Stroke length: up to 60 mm: Speed: up to 370 mm/s: Frequency: 0.01 Hz to 10 Hz: Rotational reciprocating .Historical/Traditional Test Geometry. The classic work of Thurston 1, Martens 2, Stribeck 3 and Hersey 4 were done using a journal-bearing geometry, which possesses all of the above requirements (Figure 3). An instrumented journal-bearing test allows for evaluation of the friction over a range of relative velocities and/or loads.

The more usual arrangement is Fig 1 The simple reciprocating friction and wear tester 0301-679X/80/010011"05 .00 1980 IPC Business Press TRIBOLOGY international February 1980 11 Moore and Noah - Friction and wear tester pneumatic loading of the test sample, as shown in Fig 3. Here, a pneumatic load cylinder under the action of air pressure .

Wide discrepancies in the chosen parameters make model tests complex and difficult to compare. There are investigations that compare reciprocating and rotating test methods with different results depending on the test method [9], [10].The common understanding is that test parameters should be as close as possible to the real contact situation in the engine. The large amplitude of the friction coefficient caused by reciprocating friction affects the analysis of the experimental results. Therefore, Fig. 5 (a) results from fourier low-pass filtering (cut-off frequency is 0.5). Fig. 5 (b) and Fig. 5 (c) are the local enlarged images of positions A and B in Fig. 5 (a), respectively. The observation .

linear wear friction testing

28 de jul. de 2023 · Subscribe for more anime content 💙#jujutsukaisen #gojo #jjk #gojoedit #fyp #trending

Reciprocating Friction Tester distribute|high frequency friction tester